You’ve invested in quality microfiber towels1, but they’re losing their magic. They feel stiff and no longer absorb like they used to. The problem might be your dryer.

You should not put microfiber towels in the dryer because high heat2 damages their delicate fibers. This damage melts the fibers together, which ruins their absorbency3 and cleaning ability. It also makes them stiff and rough. Air drying is the best way to preserve their quality.

I’ve been in the microfiber manufacturing business for years, and the most common issue I see is damage from improper care. Many clients, from car detailers to hotel suppliers, come to me wondering why their towels fail prematurely. The answer is almost always the same: they are being machine dried with heat. The damage goes beyond just a loss of softness. Let’s break down exactly what happens inside that hot dryer and why it’s so bad for your investment.

How does heat damage the structure of microfiber towels?

You expect your towels to last, but the dryer can shorten their life dramatically. The heat literally cooks the very fibers that make them effective, destroying your product from the inside out.

High heat melts the tiny polyester and polyamide fibers in microfiber. This process, known as fusing4, clumps the individual strands together, destroying their special star-like shape. This eliminates the microscopic pockets that are designed to trap dirt and absorb large amounts of water, rendering the towel useless.

The Science Behind the Damage

To understand the damage, you first need to understand what microfiber is. It’s a synthetic blend, typically of polyester and polyamide. During manufacturing, the fibers are split into incredibly fine strands, creating a massive surface area with millions of tiny "hooks." These hooks are what grab onto dust and absorb liquids so effectively. When you introduce high heat from a dryer, you are essentially melting plastic. The delicate hooks and star-shaped fibers fuse together into hard, useless lumps. The towel loses its softness and its ability to clean. I once worked with a large distributor in Europe who was getting customer complaints about their towels. We discovered their care instructions mistakenly recommended tumble drying. Once they changed the instructions to "air dry only," the complaints stopped completely. This shows how critical proper drying is.

Here is a simple breakdown of the effects:

| Feature | New Microfiber | Heat-Damaged Microfiber |

|---|---|---|

| Fiber Shape | Split, star-like with many hooks | Fused, clumped, and melted |

| Absorbency | Extremely high | Low; repels water |

| Texture | Soft and slightly grippy | Stiff, rough, and abrasive |

| Cleaning Power | Excellent; traps dirt and dust | Poor; pushes dirt around |

Are there hidden costs and risks to machine drying microfiber?

You might think the dryer is just a simple convenience. But it could be costing you more than just time. These hidden costs and risks can impact your bottom line and product quality.

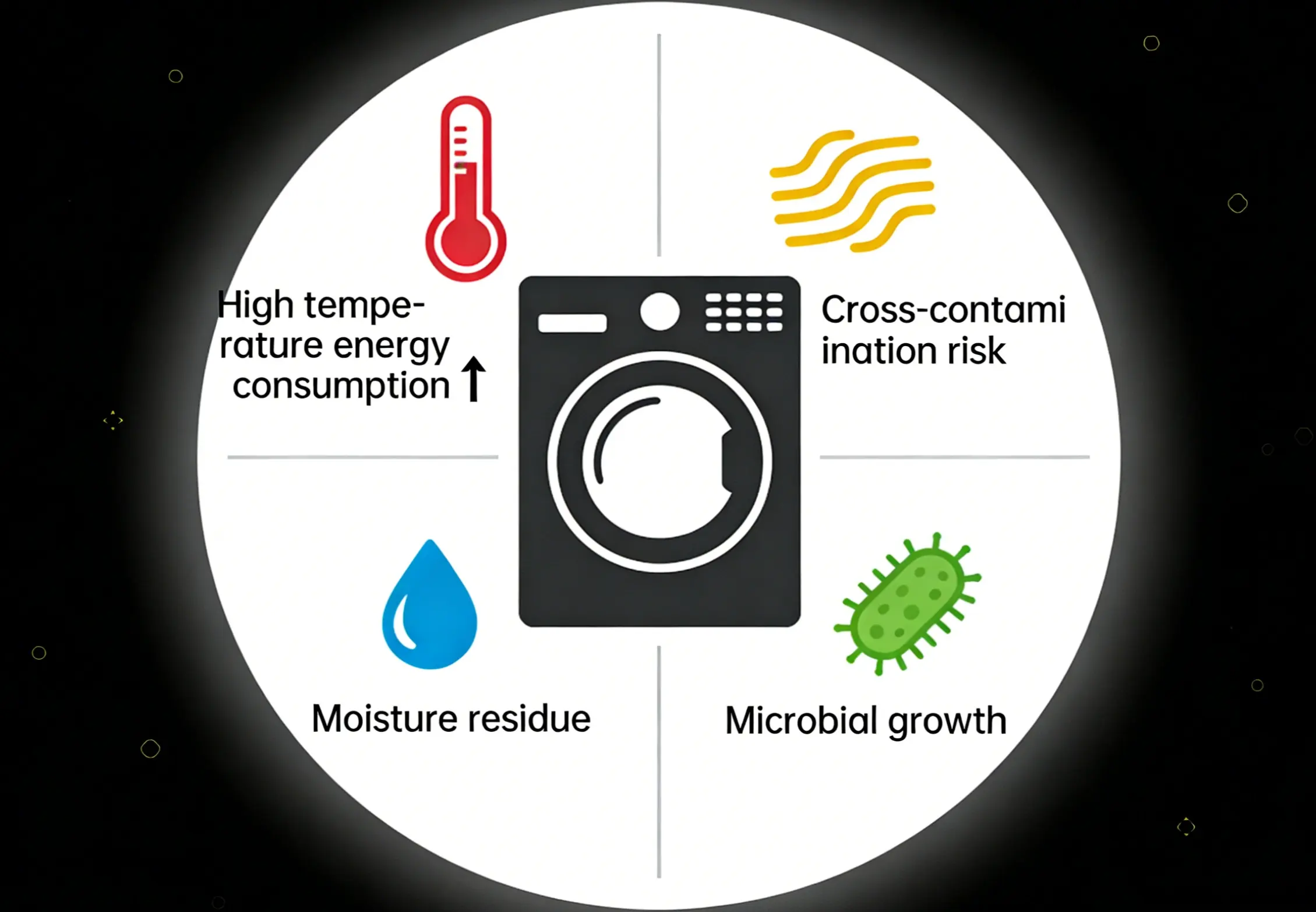

Machine drying microfiber not only consumes unnecessary energy, adding to your costs, but it can also create other problems. The heat can cause lint from other fabrics to melt onto the microfiber. Also, using a low-heat setting to avoid melting can lead to incomplete drying, creating a breeding ground for bacteria.

Analyzing the True Cost of Drying

As a manufacturer, we always think about efficiency and long-term value for our clients. Machine drying introduces several avoidable problems. First is the direct energy cost5. Microfiber air dries very quickly on its own, so using a machine is simply a waste of electricity. For any business using towels in bulk, like a hotel or car wash, the savings from air drying6 add up significantly over a year. Second, there’s the risk of contamination. If you dry microfiber with cotton towels, the lint from the cotton will get trapped in the microfiber. The heat can then fuse this lint permanently onto the fibers, ruining the towel’s non-linting quality. This is a disaster for applications like car detailing or electronics cleaning. Finally, there’s the bacteria risk7. Many people try to compromise by using a "low heat" setting. The problem is that this often leaves the towels damp in the center. A warm, damp environment is the perfect place for bacteria and mildew to grow, leading to bad odors and unhygienic cloths.

This table compares the different methods:

| Drying Method | Energy Cost | Risk of Damage | Bacteria Risk |

|---|---|---|---|

| High-Heat Dry | High | Very High | Low (if fully dried) |

| Low-Heat Dry | Medium | Medium | High (if not fully dried) |

| Air Dry | Zero | None | Low (if properly ventilated) |

What is the best way to dry microfiber towels for longevity?

You want your microfiber products to perform perfectly for your customers. Improper drying is the number one cause of failure. So what’s the simple, foolproof method to protect them and your reputation?

The best way to dry microfiber towels is to simply air dry them. Hang them on a clothesline or a drying rack8 in a well-ventilated area. This method costs nothing, uses no energy, and completely prevents heat damage, preserving the towel’s softness, absorbency, and cleaning power.

The Professional’s Guide to Air Drying

This is the exact advice we give all our wholesale and OEM clients to include on their product care labels9. It’s the only way to guarantee the longevity of the product. The process is simple and effective. First, after washing the towels in cold water10 with a gentle detergent11 (and never with fabric softener), gently wring out the excess water. Don’t twist them too aggressively. Second, give each towel a good, sharp shake. This helps to fluff up the fibers, which separates them and allows air to circulate more freely, speeding up the drying time. Third, hang them properly. The key is good air circulation. Drape them over a drying rack, a clothesline, or even a shower rod. Make sure they are not folded over or bunched up, as this can trap moisture.

Of course, some clients ask, "What if I absolutely must use a dryer?" In a high-volume commercial setting, time can be a factor. If you must, use the no heat or air fluff setting only. This just tumbles the towels with room-temperature air. It’s also crucial to dry them in a separate load from any cotton or other lint-producing fabrics. This prevents cross-contamination.

Conclusion

In short, avoid the dryer to protect your microfiber towels. Air drying is the simple, free way to maintain their quality, extend their life, and ensure top performance for your customers.

-

Explore this resource to learn how to properly care for microfiber towels and extend their lifespan. ↩

-

Understanding the impact of high heat can help you avoid damaging your microfiber towels. ↩

-

Discover the science behind absorbency and how to keep your towels performing at their best. ↩

-

Understanding fusing can help you prevent damage to your microfiber towels. ↩

-

Find out how switching to air drying can significantly reduce energy expenses for your business. ↩

-

Learn why air drying is the best method for maintaining the quality of your microfiber towels. ↩

-

This resource explains the health risks associated with improperly dried microfiber towels. ↩

-

Get tips on how to effectively use a drying rack to air dry your microfiber towels. ↩

-

Explore best practices for product care labels to ensure proper maintenance of microfiber towels. ↩

-

Learn the importance of washing microfiber towels in cold water for optimal care. ↩

-

Learn about the best detergents to use for maintaining the quality of microfiber towels. ↩