Microfiber

If you’re looking for high-quality microfiber cleaning cloths for wholesale or bulk orders,

👉 [Visit our dedicated landing page to get a quote](https://meet-clean.com/wholesale-microfiber-cleaning-cloths/) and discover customization options for your needs.

Technology, Applications, Cost, Customization, and Global Supply Strategy

1. Executive Summary

In an era where cleanliness, sustainability, and cost-efficiency are mission-critical, microfiber cleaning cloths have emerged as one of the most transformative innovations in the global cleaning and hygiene sector.

This guide is tailored for B2B professionals—whether you’re sourcing for retail, hospitality, automotive detailing, or institutional cleaning. It provides a complete deep dive into:

-

How microfiber works and why it outperforms traditional materials

-

Types of microfiber cloths and how to select the right build for your business

-

Technical specifications that matter: GSM, blend ratios, fiber cut, and edge finish

-

Application strategies across industries with real use cases

-

Cost-benefit analyses with long-term ROI insights

-

Customization opportunities for brands and bulk purchasers

-

Global sourcing best practices and supplier evaluation methods

This is not a surface-level overview, but a manufacturing-grade framework to help you make confident, optimized, and scalable purchasing decisions.

2. Understanding Microfiber Technology

What Is Microfiber?

Microfiber is a synthetic fiber finer than one denier, often 100 times thinner than human hair. It is typically made by blending polyester (for structure) and polyamide/nylon (for absorbency and softness) in proportions like 80/20 or 70/30.

These fibers are split during processing to form microscopic edges. This split-structure design is what gives microfiber cloths their signature characteristics:

| Performance Attribute | Root Mechanism |

|---|---|

| High Absorption | Increased surface area traps liquid via capillary action |

| Superior Dust Trapping | Electrostatic charge and split fibers grab particles |

| Lint-Free Cleaning | Finer-than-paper structure ensures no fiber shedding |

| Rapid Drying | Hydrophobic base material accelerates evaporation |

| Chemical-Free Cleaning | Physical trapping replaces chemical solvents |

📌Important Note: Not all microfiber is created equal. Non-split, lower-grade polyester cloths do not offer these performance benefits and are often misleadingly marketed as “microfiber.”

Microfiber is a synthetic fiber finer than one denier—often 100 times thinner than human hair—commonly composed of polyester and polyamide (nylon). These ultra-fine fibers are engineered to increase surface area and improve absorbency, making them highly effective for cleaning applications.

To explore the material types, build quality, and use cases of professional-grade microfiber cloths, visit our Microfiber Cleaning Cloth product page.

For a broader overview of microfiber composition and fiber classification, you can also refer to this Wikipedia article.

Technical Composition & Fiber Grades

-

Polyester: Makes up the majority of the structure; hydrophobic, durable, and defines shape

-

Polyamide (Nylon): Enhances water absorption and softness; improves wiping performance

-

Denier Rating: Lower denier = finer fiber. High-performance microfiber is typically < 0.5 denier

-

Split vs. Unsplit Fiber: Split = high-performance cleaning; Unsplit = cheap, limited functionality

Manufacturers like Meet Clean utilize industry-certified yarns and specialized equipment to ensure consistent split ratios, fiber density, and longevity.

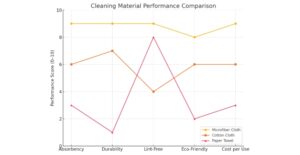

Microfiber vs. Conventional Materials (Technical Comparison)

| Metric | Microfiber | Cotton | Paper Towel |

|---|---|---|---|

| Fiber Diameter | <1 denier | 3–5 denier | ~10 microns |

| Water Absorption | Up to 7x its weight | 2–3x its weight | <1x its weight |

| Reusability | 30–50 washes | 10–20 washes | Single use |

| Drying Time | Fast | Medium | N/A |

| Surface Abrasion | Low | Moderate (scratches glass) | Low |

| Lint-Free | Yes | No | Yes |

✅ Conclusion: Microfiber offers performance at both the material and operational levels, improving not just surface cleanliness but cleaning workflows, inventory planning, and end-user experience.

3. Types of Microfiber and Their Structural Differences

Microfiber cloths are not one-size-fits-all. Depending on weave pattern, GSM, edge finish, and usage intent, they vary dramatically in performance and price.

🔸 Based on Fabric Construction:

| Type | Description | Ideal Use |

|---|---|---|

| Warp-Knitted | High-density, strong loops, durable structure | Car detailing, industrial, commercial cleaning |

| Weft-Knitted (Terry) | Softer loops, good absorbency, budget-friendly | Household, light duty |

| Waffle Weave | Honeycomb texture, high water retention | Kitchen drying, spa towels |

| Coral Fleece | Fluffy surface, thick pile | Polishing, sensitive surfaces |

| Suede Microfiber | Ultra-smooth, low-pile | Electronics, glasses, optical lenses |

| Twisted Loop Pile | Dense twisted fiber pattern | High-end car drying, heavy spill cleanup |

| Flat Knit / PVA-Coated | Rubberized or coated for glass/mirror streak-free cleaning | Windows, restaurants, clinics |

🔸 Based on Product Format:

| Format | Description | Application |

|---|---|---|

| Cut Sheets (30x30cm) | Most common, stackable | Bulk industrial use, home cleaning |

| Tear-Off Rolls | Pre-perforated rolls, disposable but reusable | Cleaning services, kitchen prep stations |

| Boxed Wipes | Tissue-style dispensing, retail-friendly | Supermarkets, hospitals, food service |

| Kraft Tube Pack | Consumer packaging with branding space | Private label, e-commerce, gifting |

| SRP Tray-Display Units | Retail shelf-ready with branding | Supermarkets, promotions |

📌 Buyer Tip:

-

Tear-off rolls save labor and time in high-turnover environments

-

Coral fleece enhances perceived value in retail/eCommerce

-

Waffle weave is preferred for moisture control

4. Key Specification Metrics That Affect Performance

As a B2B buyer, understanding technical specifications isn’t optional—it’s essential. These numbers directly affect your cloth’s absorbency, longevity, user experience, and branding compatibility.

Here are the five most critical metrics you must evaluate before placing any order:

4.1 GSM (Grams per Square Meter)

GSM determines cloth thickness and absorbency. It’s not just a weight indicator—it reflects intended purpose.

GSM Range Profile Recommended Use 180–240 Lightweight, thin, fast-dry Budget projects, give-away cloths, low-duty 250–320 Balanced durability & feel Standard commercial cleaning, hospitality 330–400 High-absorbency, plush feel Automotive detailing, eCom packaging sets 400–450+ Premium luxury Spa towels, high-end private label sets 🧪 Real-World Insight:

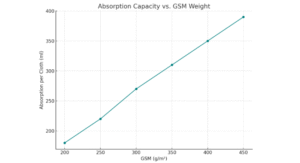

A 350 GSM cloth typically absorbs up to 300–320ml of water. In comparison, a 220 GSM cloth may only absorb 180–200ml.📊 Refer to the chart “Absorption vs GSM” for visual comparison.

4.2 Blend Ratio (Polyester vs Polyamide)

The common standard is 80/20 (polyester/nylon), but for softer or more water-loving products, some opt for 70/30.

Ratio Performance Effect 80/20 Balanced strength + absorption, lower cost 70/30 Softer, faster absorption, slightly higher cost 100% Polyester Lower quality, often unsplit fiber = ineffective cleaning ✅ Pro Tip: Always confirm if your supplier uses split microfiber. Unsplitted polyester offers none of the true microfiber benefits.

4.3 Fiber Denier

-

<0.5 denier = Ultra-fine, better for polishing and glass

-

0.7–1.0 denier = Industry standard for cleaning use

-

1.2 denier = Too coarse, may scratch surfaces

4.4 Edge Stitching

Edge Type Strength Aesthetics Cost Overlock Stitch High Moderate Low Folded Seam Medium High Medium Ultrasonic Cut Low–Med Premium Look Higher 📌 Folded seams are preferred in retail and cosmetic brands; overlock is preferred in cleaning services.

4.5 Dyeing Process & Color Fastness

-

VAT-dyed fabrics hold up longer

-

Reactive dye = deeper color, better wash performance

-

Avoid “direct dye” methods for repeat-use products

✅ Always request a color fastness report if selling in Japan, Europe, or US.

5. Industry-Specific Application Strategies

Microfiber products are not used the same way in every sector. B2B buyers must align product selection with actual cleaning protocols, user behavior, and supply chain flow.

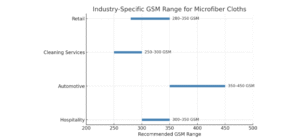

🏨 Hospitality & Hotels

-

Common specs: 300–350 GSM, 80/20, 30x40cm, folded edge

-

Best products: Warp-knit cloths, color-coded by cleaning zone

-

Why: Fast-drying = faster room turnover; uniformity = easier staff training

Pro Tip: Create a “Housekeeping Kit” pack (mirror cloth + all-purpose + bath towel) for hotel procurement teams.

🚗 Automotive Detailing

-

Common specs: 320–450 GSM, coral fleece, twisted loop, 40×40 or 60×80 cm

-

Why: Paint-safe, high pile absorbs water without scratching

-

Preferred edge: Ultrasonic or seamless to prevent scratching

Bundle idea:

-

Glass cloth + interior cloth + drying towel set → sell as full kit to car franchises.

🧼 Cleaning Companies & Janitorial Services

-

Key traits: Bulk packaging, tear-off rolls, high durability

-

Preferred GSM: 250–300 GSM

-

Why: Cost control, high usage frequency, repeat washing

Popular format:

-

Tear-off microfiber rolls (5m or 10m) reduce labor, enable standardized cleaning quantity.

🛒 Retail & Private Label

-

Focus: Branding, aesthetics, packaging design

-

Best SKU: 3pc set in kraft tube or color card

-

Ideal GSM: 300–350

-

Edge: Folded seam or laser cut

📌 Tip: Add a hanging hole tag or QR label for eco story → improves shelf performance.

6. Cost-Benefit Analysis with Lifecycle ROI

💸 Upfront vs Lifecycle Cost

Microfiber may cost more per piece, but costs far less per use.

Material Unit Cost Reuse Cycles Effective Cost per Use Microfiber $0.50 30–50 $0.01–0.016 Cotton Cloth $0.30 10–15 $0.02–0.03 Paper Towel $0.02 1 $0.02 (and wasteful) 📌 Savings come from:

-

Reduced purchase frequency

-

Lower detergent usage

-

Less drying energy

-

Less labor due to faster cleaning time

-

♻️ Environmental ROI

Switching to microfiber aligns with global sustainability trends:

-

Fewer chemicals

-

Less water consumption

-

Lower packaging volume

-

Longer product lifespan

-

Easy to recycle (PET-based GRS certified cloths)

✅ Consider using GRS-certified recycled yarns and compostable packaging for carbon-conscious clients.

-

7. Packaging & Branding Options for Microfiber Cloths

Packaging is no longer a passive layer of protection—it’s your first moment of brand impact, especially in wholesale, retail, or eCommerce environments. The right packaging not only enhances visual appeal but also:

-

Protects fibers from contamination

-

Improves retail shelf visibility

-

Supports inventory control

-

Boosts consumer trust and unboxing experience

🔸 7.1 Packaging Formats

| Packaging Type | Description | Ideal Use Case |

|---|---|---|

| Shrink Wrap (bulk) | Minimal cost, easy to palletize | Cleaning services, B2B bulk |

| Kraft Paper Tube | Strong visual identity, recyclable | Retail, eCommerce brands |

| Color Card + Plastic Hook | Showcases brand + ready to hang | Supermarkets, chain stores |

| SRP Box (Shelf-Ready Packaging) | Branded outer carton for display | Trade show, seasonal promotion |

| Boxed Wipes (pop-up) | Dispenses like tissues | Food service, hospitals |

📌 Retail Tip: For premium presentation, use 3-pc or 5-pc combo packs with themed colorways and story cards (“Eco, Durable, Reusable”).

🔸 7.2 Label & Logo Options

| Label Type | Placement | Best For |

|---|---|---|

| Heat Transfer | Discreet, inside | Minimalist brands |

| Woven Tag | Side seam | Common for logo visibility |

| Printed Card Insert | Inside packaging | For story or care guide |

| Barcode Sticker | Outer packaging | Retail compliance |

🎯 Pro Insight: Combine logo labeling with care instructions and material claim (e.g., “80/20, 350gsm, 30+ washes”) to support consumer confidence.

8. Customization Workflow: From Quote to Production

Launching a microfiber line or private label SKU doesn’t have to be complex. A professional manufacturer will offer a turnkey customization process covering design, sampling, production, and logistics.

🔁 Step-by-Step Workflow

-

Requirements Collection

-

Size, GSM, blend, color

-

Packaging style

-

Logo file or branding guidelines

-

-

Quotation & MOQ Confirmation

-

Get unit cost breakdown (cloth + printing + packaging)

-

Confirm MOQ (usually 2,000–5,000 pcs)

-

-

Sample Preparation (5–7 Days)

-

Branded prototype, or plain sample for material approval

-

Color-matched to Pantone or product swatch

-

-

Mass Production (10–20 Days)

-

Cutting → Sewing → QC → Packaging

-

Bulk packed by SKU, size, or region

-

-

Shipping Support

-

FOB, CIF, DDP options

-

Carton labeling with SKU/barcode

-

Documentation for customs (MSDS, CO, packing list)

-

📌 Tip: Always ask for a pre-shipment photo/video approval before loading—helps avoid misprints or labeling errors.

🔧 Optional Add-ons

-

Barcode generation

-

Box design service (AI template format)

-

Instruction leaflet insertion

-

Carton optimization for 20GP/40HQ containers

✅ Meet Clean offers full OEM/ODM services with flexible MOQ and English-speaking support team.

9. Real Buyer Case Studies by Region & Industry

Let’s explore how different businesses have successfully implemented microfiber products based on their industry needs and supply priorities.

🇺🇸 USA | Cleaning Franchise – Tear-Off Microfiber Roll

Challenge: High staff turnover, inconsistent cloth hygiene, overuse of paper wipes.

Solution: Switched to 10m microfiber rolls with 55 perforated sheets/roll.

Result:

-

Cleaning time reduced by 28%

-

Reduced procurement cost by 34% per site

-

Less cross-contamination risk

🇯🇵 Japan | Retail Chain – Boxed Display Cloths

Challenge: Shift toward sustainable alternatives in household cleaning aisle

Solution: 3-pack 300gsm cloths in kraft tube with minimalistic design

Result:

-

21% lift in category sales

-

Increased eco-brand equity

-

Fully REACH-compliant, passed Japanese odor tests

🇩🇪 Germany | Auto Detailer Network

Challenge: Need for premium cloths that won’t scratch high-end car surfaces

Solution: 400gsm twisted loop + ultrasonic edge, 40×60cm, laser-logo print

Result:

-

Reduced drying time

-

Improved customer NPS

-

Enabled sale of premium kits (retail value: €14.99/cloth)

🌏 Global | Amazon Sellers – Starter Private Label Kit

SKU: 3-pack gray, 330gsm, folded edge + color card

Packaging: Bilingual instructions (EN+DE/FR) + barcode

Result:

-

18–26% conversion uplift vs unbranded competitors

-

Repeat purchase rate >40%

-

Logistics optimized for FBA carton sizing

10. Global Market Trends & Demand Shifts (2019–2024)

The global microfiber cleaning cloth market has seen compound growth across all regions, driven by rising hygiene awareness, cost control in professional cleaning, and sustainability trends.

📊 Key Trends by Region:

🇺🇸 United States

-

Annual volume exceeded 400 million rolls in 2024

-

High adoption in automotive, commercial cleaning, and retail chains

-

Cost-efficiency and labor savings are key drivers

🇯🇵 Japan

-

Demand surged 16% YoY (2023–2024) in household and hotel sectors

-

Focus on odor control, anti-bacterial properties, and compact packaging

-

Retail prefers boxed or SRP-ready formats

🇪🇺 Europe

-

Strong push from sustainability and REACH regulations

-

Green-certified suppliers preferred by facility management companies

-

Growing demand for GRS-certified and OEKO-TEX microfiber products

🧠 Emerging Global Opportunities

-

South America & Southeast Asia: Mid-range priced microfiber for hospitality chains

-

eCommerce Boom: Amazon, Shopee, and Rakuten sellers seek private label packaging

-

Sustainable Initiatives: More buyers ask for recycled PET yarns and compostable bags

✅ Buyers aligned with eco-compliance + smart packaging will be the biggest winners over the next 3–5 years.

11. Frequently Asked Questions (FAQ)

Q1: How many times can microfiber cloths be washed?

Most standard microfiber cloths endure 30–50 machine washes, depending on detergent and temperature.

Q2: What’s the MOQ for custom logo and packaging?

Most factories support custom orders from 2,000–3,000 pcs per spec, with pricing tiers for volume.

Q3: Can microfiber cloths be used without cleaning chemicals?

Yes. In many cases, especially with split-fiber structures, water alone can remove up to 98% of surface bacteria.

Q4: Are your products compliant with REACH / OEKO-TEX / GRS?

Meet Clean supports full certification on request, including GRS for recycled microfiber, OEKO-TEX Standard 100, and REACH for Europe.

Q5: Can I get a sample before placing bulk orders?

Absolutely. We offer free branded or unbranded sample kits, typically shipped within 3–5 working days via UPS/FedEx.

12. Strategic Takeaways for B2B Buyers

✅ Microfiber isn’t a trend—it’s a scalable, sustainable tool.

From performance to cost to environmental impact, microfiber cloths solve real cleaning problems across industries.

✅ Choosing the right GSM, weave, and edge finish makes or breaks usability in your market.

✅ Packaging = brand leverage. In wholesale or retail, smart packaging differentiates your offer and supports storytelling.

✅ Certifications and factory systems matter. Avoid cheap imports without split fiber or QC records.

✅ Reorder speed, MOQ flexibility, and sampling responsiveness are non-negotiables for a long-term supplier.

📍 13. Get Started: Samples, Quotes & Custom Kits

Whether you’re sourcing for a hotel chain, automotive detailing network, or launching your private label brand on Amazon, we’re here to help you scale.

💬 Contact Us Today to Get:

-

Free material & packaging samples

-

Custom quotation based on your specs

-

Digital mockups for branding review

-

Full OEM/ODM support with low MOQs

-

Export-ready documentation and fast logistics

📧 Email: sales@meet-clean.com

🌐 Website: www.meet-clean.com

Ready to upgrade your cleaning solutions with premium microfiber cloths?

👉 [Click here to view our Microfiber Cleaning Cloths Landing Page](https://meet-clean.com/wholesale-microfiber-cleaning-cloths/) and request a free quote today!