For textile buyers, designers, and manufacturers, GSM (Grams per Square Meter)1 is more than a technical metric—it’s the cornerstone of cost control, quality assurance, and product performance. A wrong GSM judgment can lead to mismatched fabric thickness for end products, inflated sourcing costs, or even customer complaints.

Unlike generic guides that only cover basic formulas, this article combines lab-grade measurement methods2, field-friendly tricks3, and scenario-based application strategies4 to help you master GSM from every angle. Whether you’re sourcing ultra-fine fiber cleaning cloths for global clients or selecting fabrics for apparel lines, this guide will turn GSM into your competitive advantage.

What Exactly Is Fabric GSM & Why Does It Matter?

GSM refers to the weight of one square meter of fabric in grams. It directly reflects the fabric’s density, thickness, and material consumption—but it does not equal quality on its own.

Core Roles of GSM in Textile Business

- Cost Control5: Higher GSM means more fiber usage per unit area. For example, a 200 GSM ultra-fine fiber cleaning cloth uses 33% more raw material than a 150 GSM one, directly affecting the ex-factory price.

- Quality Matching6: A cleaning cloth for industrial use requires 250–300 GSM for durability, while a household wipe only needs 120–180 GSM for softness.

- International Sourcing Compatibility7: Suppliers in the US often use oz/yd² (ounces per square yard), while European and Asian suppliers default to GSM. Misconversion can lead to order errors.

- Production Consistency8: Reputable manufacturers (like MeridaTex) control GSM within a ±3–5% tolerance range to ensure batch consistency.

Proven Methods to Calculate Fabric GSM (From Lab to Field)

The core formula for GSM is universal:

GSM = Sample Weight (g) / Sample Area (m²)

The difference lies in the accuracy of tools and operation methods. Below are three methods tailored to different scenarios.

Method 1: Lab-Grade Measurement (For Quality Inspection & Batch Verification)

This method is suitable for factory quality control or third-party testing, with an error rate of less than ±1%.

Required Tools

Precision electronic scale9 (0.001g accuracy), fabric sample cutter (standard 10cm×10cm), non-woven pad (to prevent fabric slipping during cutting).

Step-by-Step Operation

- Prepare the sample: Select a representative part of the fabric (avoid edges or defective areas, as these have uneven GSM).

- Cut the standard sample: Use the fabric cutter to cut 5–10 pieces of 10cm×10cm squares (area = 0.01 m² per piece).

- Weigh the samples: Place the non-woven pad on the scale to zero it out, then weigh each sample individually and record the data.

- Calculate the average GSM: Sum the weights of all samples, divide by the number of samples to get the average single-piece weight, then divide by 0.01 m².

Example: 5 samples weigh 1.52g, 1.55g, 1.53g, 1.54g, 1.56g respectively.Average weight = (1.52+1.55+1.53+1.54+1.56)/5 = 1.54gGSM = 1.54g / 0.01m² = 154 GSM

Method 2: Field-Friendly Measurement (For Sourcing Trips Without Equipment)

This method is for buyers who need to check GSM on-site, with an error rate of ±3–5%.

Required Tools

Ruler, scissors, mobile phone scale (or portable digital scale10 with 0.01g accuracy).

Step-by-Step Operation

- Mark the sample area: Use a ruler to draw a 20cm×20cm square on the fabric (area = 0.04 m²; larger samples reduce error).

- Cut and weigh: Cut the square along the marked lines, and weigh it with a portable scale.

- Calculate GSM: Divide the sample weight by 0.04 m².

Example: A 20cm×20cm sample weighs 6.12g.GSM = 6.12g / 0.04m² = 153 GSM

Method 3: Estimation Method (For Emergency Situations Only)

This method is a last resort when no tools are available, with an error rate of ±10–15%.

Key Principle

Use the weight of a known object as a reference. For example, a standard A4 paper weighs about 5g, with an area of 0.0625 m² (21cm×29.7cm).

Step-by-Step Operation

- Compare fabric and paper: Cut a fabric sample of the same size as A4 paper, and feel its weight relative to A4 paper.

- Estimate weight: If the fabric feels twice as heavy as A4 paper, its weight is about 10g.

- Calculate GSM: GSM = 10g / 0.0625m² = 160 GSM

GSM Unit Conversion11: Solve International Sourcing Confusion

When dealing with overseas clients (e.g., US buyers using oz/yd²), accurate unit conversion is critical. Below is a no-error conversion table and calculation formula.

Core Conversion Formulas

- oz/yd² to GSM: GSM = oz/yd² × 33.9057

- GSM to oz/yd²: oz/yd² = GSM ÷ 33.9057

Quick Conversion Table

| oz/yd² | GSM (Approx.) | Common Application Scenarios |

|---|---|---|

| 2 oz | 68 GSM | Lightweight scarves, voile |

| 4 oz | 136 GSM | T-shirts, bed sheets |

| 6 oz | 203 GSM | Casual shirts, cleaning wipes |

| 8 oz | 271 GSM | Denim jeans, canvas bags |

| 12 oz | 407 GSM | Winter coats, industrial fabrics |

Practical Tip: For Peruvian or Spanish-speaking clients, use the term “gramaje por metro cuadrado” instead of GSM to avoid communication misunderstandings.

GSM vs. Fabric Performance12: It’s Not Just About Thickness

A common misconception is that higher GSM = better fabric. In reality, the optimal GSM depends on the fabric fiber type and end-use scenario.

Key Influencing Factor: Fiber Density

Different fibers have different densities, so the same GSM can result in different thicknesses:

- Polyester fiber: Density = 1.38 g/cm³ (lighter, thinner at the same GSM)

- Cotton fiber: Density = 1.54 g/cm³ (heavier, thicker at the same GSM)

- Ultra-fine fiber (Microfiber): Density = 1.20–1.30 g/cm³ (softer, more absorbent at 150–200 GSM)

Example: A 200 GSM polyester cleaning cloth is thinner than a 200 GSM cotton cloth, but it has better water absorption and durability—making it more suitable for household cleaning products.

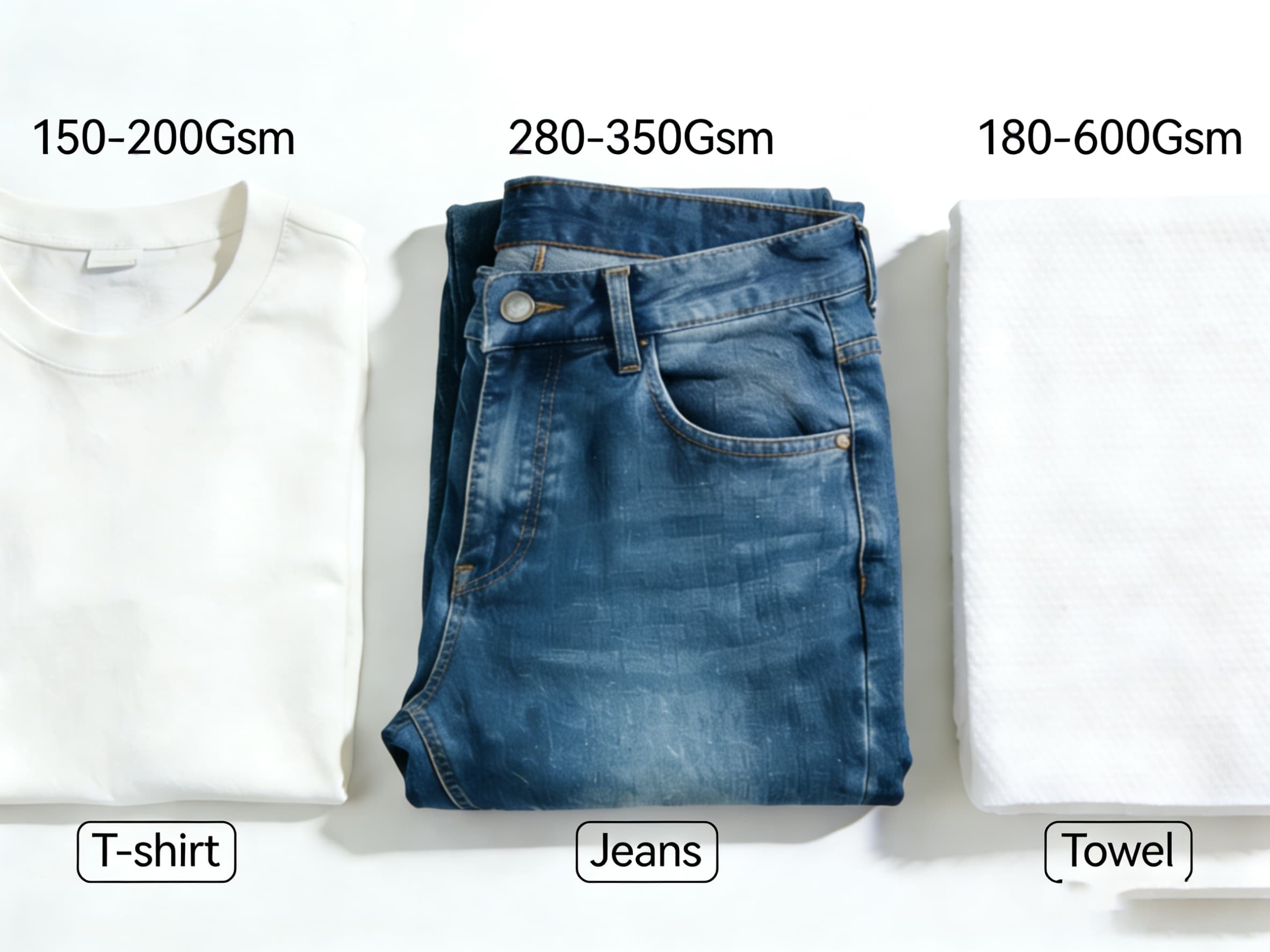

GSM Selection Guide: Match the Right Value to Your Product

Choosing the right GSM is the key to balancing product performance and cost. Below is a scenario-based GSM selection table for common textile products.

| Product Category | Recommended GSM Range | Core Requirements Met by GSM |

|---|---|---|

| Household Microfiber Cleaning Cloths | 120–180 GSM | Softness, water absorption, cost control |

| Industrial Heavy-Duty Wipes | 250–300 GSM | Durability, lint-free performance |

| T-shirts & Casual Shirts | 150–200 GSM | Breathability, shape retention |

| Denim Jeans | 280–350 GSM | Wear resistance, stiffness |

| Winter Jackets | 400+ GSM | Warmth, windproof performance |

Pro Tip for Manufacturers: For export products, adjust GSM according to regional needs. For example, Peruvian consumers prefer lightweight (120–150 GSM) cleaning cloths due to the warm climate, while European clients need 180–200 GSM for better durability.

Common Mistakes to Avoid in GSM Measurement13

Even with the right formula, small mistakes can lead to large errors. Here are 5 common pitfalls to avoid:

- Sampling from fabric edges: Edges have uneven fiber density14, leading to inaccurate GSM values.

- Ignoring fabric moisture: Humid environments increase fabric weight—dry samples to room temperature before weighing.

- Using low-precision scales: Scales with 0.1g accuracy can cause a ±10 GSM error; choose 0.01g accuracy for field measurements.

- Cutting irregular samples: Crooked cuts reduce the actual area of the sample; use a template or cutter for standard squares.

- Calculating with wrong area units: Confusing cm² with m² is the most common mistake—remember: 1 m² = 10,000 cm².

Conclusion

GSM is a bridge connecting textile sourcing, production, and sales. Mastering its calculation methods and application strategies can help you:

- Reduce sourcing costs by 10–15% by avoiding over-specification of GSM.

- Improve product quality consistency by controlling GSM tolerance within ±3%.

- Enhance international communication efficiency by mastering unit conversion.

Whether you’re a buyer inspecting samples on-site or a manufacturer optimizing product specifications, this guide will turn GSM from a technical jargon into a practical tool for business growth.

-

Understanding GSM is crucial for cost control and quality assurance in textile sourcing and manufacturing. ↩

-

Explore precise lab-grade methods to ensure accurate GSM measurements for quality control. ↩

-

Learn practical tricks for on-site GSM measurement without specialized equipment. ↩

-

Discover strategies tailored to different textile applications to optimize GSM usage. ↩

-

Understand how GSM influences material costs and pricing strategies in textile production. ↩

-

Learn how to match fabric quality with appropriate GSM for various applications. ↩

-

Find out how to navigate GSM conversions for seamless international textile sourcing. ↩

-

Explore the significance of maintaining GSM consistency for product quality. ↩

-

Discover the importance of using high-accuracy scales for reliable GSM results. ↩

-

Find out how to effectively use portable scales for on-the-go GSM checks. ↩

-

Get accurate conversion formulas to avoid errors in international textile transactions. ↩

-

Explore the connection between GSM and fabric performance to make informed choices. ↩

-

Learn about common pitfalls to avoid for accurate GSM measurement in textiles. ↩

-

Understand the relationship between fiber density and GSM for better fabric selection. ↩