1 Why Microfiber Matters

Elevating Everyday Cleaning with Advanced Material Science

In the world of professional cleaning, efficiency, hygiene, and sustainability are no longer just buzzwords—they’re operational imperatives. That’s where microfiber cleaning cloths come in. With the rise of smarter facilities, greener compliance goals, and cost-cutting pressures, microfiber has quietly become the backbone of modern cleaning strategies, from hospitality to healthcare and from households to heavy industry.

This chapter will explore:

-

What makes microfiber different from traditional fabrics

-

The science behind its performance

-

Tangible B2B benefits across various industries

-

Supporting market data and visual comparisons

What Is Microfiber?

Microfiber is a synthetic fiber typically made of polyester and polyamide (nylon), with a fiber thickness less than 1 denier (or about 1/100th the diameter of a human hair). These ultra-fine fibers are split during manufacturing to increase surface area and create microscopic spaces that trap dirt, moisture, and oil effectively.

Key Properties:

-

Fiber diameter: 0.1–0.3 dtex (vs 1–2 dtex for cotton)

-

High capillary action = excellent absorbency

-

Positive static charge = attracts dust and particles

-

Non-abrasive, lint-free, fast-drying

Why It Outperforms Traditional Cloths

When compared to standard cotton or viscose-based rags, microfiber performs significantly better in every meaningful metric:

🧽 Absorbency: Absorbs up to 7x its weight in liquid

💪 Durability: Resists tearing and degrades slower after repeated use

🔁 Reusability: Washable over 300+ times without losing effectiveness

🍃 Eco-friendliness: Reduces chemical and water use

🚫 Lint & Streak Free: Ideal for glass, screens, chrome surfaces

💰 Cost Efficiency: Higher upfront cost, lower lifecycle cost

Visual Comparison: Microfiber vs Traditional Cloths

📊 Performance Comparison:

| Metric | Traditional Cloths | Microfiber Cloths |

|---|---|---|

| Absorbency | ★★☆☆☆ | ★★★★★ |

| Durability | ★★☆☆☆ | ★★★★★ |

| Reusability | ★☆☆☆☆ | ★★★★★ |

| Eco-Friendliness | ★★☆☆☆ | ★★★★☆ |

| Lint-Free Cleaning | ★★☆☆☆ | ★★★★★ |

| Cost Efficiency | ★★☆☆☆ | ★★★★☆ |

Conclusion: While traditional cloths may seem more economical at first glance, the long-term savings, labor efficiency, and better cleaning outcomes from microfiber make it the superior option for professional and large-scale cleaning operations.

Industry Recognition & Data

-

According to a 2024 survey by the American Cleaning Institute, 78% of commercial cleaning companies report improved cleaning times and reduced chemical usage after switching to microfiber systems.

-

The European Centre for Disease Prevention and Control (ECDC) recommends microfiber for hospital cleaning due to its ability to reduce microbial load without harsh disinfectants.

-

In the US, microfiber mops and cloths have become the standard for LEED-certified green cleaning programs, contributing to sustainability goals.

Microfiber: A B2B Strategic Asset

Microfiber is no longer just a “premium option”—it’s a strategic tool for cleaning service providers, hospitality procurement teams, food factories, and OEM buyers. It meets multiple objectives at once:

✅ Enhanced performance

✅ Reduced labor and material costs

✅ Positive environmental impact

✅ Stronger brand perception for eco-conscious clients

Summary

Microfiber cloths aren’t just “better cloths”—they are an innovation that elevates everyday cleaning into a science-backed, cost-saving, sustainability-aligned operation. For B2B buyers and facility managers, microfiber is a game-changer with measurable ROI.

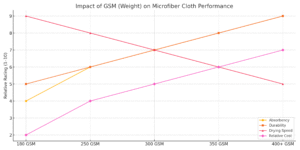

2 How GSM Affects Performance

The Science Behind Thickness, Weight, and Effectiveness in Microfiber Cloths

In the world of textile manufacturing, GSM—or grams per square meter—is one of the most important indicators of product quality. For microfiber cleaning cloths, GSM impacts everything from how well the cloth absorbs liquid, to how soft it feels in hand, to how long it lasts under repeated use.

If you’re a B2B buyer sourcing microfiber rolls, cloths, or tear-off formats, understanding GSM is crucial to matching product specifications with customer expectations and application scenarios.

What Is GSM?

GSM stands for grams per square meter, and it quantifies fabric density. The higher the GSM, the heavier and denser the fabric.

| GSM Range | Description | Typical Usage |

|---|---|---|

| 150–180 | Lightweight | Disposable or single-use wipes |

| 200–250 | Standard | General household and kitchen cleaning |

| 300–350 | Heavy-duty | Automotive, industrial, oil wiping |

| 400+ | Premium luxury grade | Optical care, electronics, luxury retail |

Formula for GSM Calculation:

GSM=Fabric Weight (g)Length (m)×Width (m)GSM = \frac{\text{Fabric Weight (g)}}{\text{Length (m)} \times \text{Width (m)}}GSM=Length (m)×Width (m)Fabric Weight (g)

GSM vs. Performance: A Measured Relationship

Microfiber’s functional attributes change significantly as GSM increases. Below is a performance comparison across 150–400 GSM cloths across 3 criteria:

📊 GSM Performance Metrics:

| GSM | Absorbency | Softness | Durability |

|---|---|---|---|

| 150 | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ |

| 200 | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| 300 | ★★★★★ | ★★★★★ | ★★★★★ |

| 400 | ★★★★☆ | ★★★★☆ | ★★★★★ |

Key Insights:

-

Absorbency increases with GSM, peaking between 250–300.

-

Softness improves significantly above 250 GSM—ideal for glass, electronics, and personal care.

-

Durability shows the most consistent improvement with GSM, especially above 200.

Choosing the Right GSM for Your Industry

For OEM clients, GSM selection should align with the product’s application scenario and market positioning. Below are some recommendations:

| Application | Recommended GSM | Reasoning |

|---|---|---|

| Car detailing | 300–400 GSM | Scratch-free buffing and superior absorption |

| Household cleaning rolls | 180–250 GSM | Balance of cost and general-purpose use |

| Industrial/oil wiping | 250–300 GSM | High durability and measurable liquid intake |

| Optical/lens care | 350–400 GSM | Extra soft for streak-free performance |

| Promotional giveaways | 150–180 GSM | Cost-effective, suitable for single use |

🧠 Pro tip: For B2B private label programs, offering multiple GSM grades (e.g. 200, 300, 380 GSM) increases market adaptability.

GSM and Cost Structure

GSM directly affects material weight per piece—and thus, the unit price. However, higher GSM often translates to fewer units required per cleaning task, extending product lifespan and reducing usage frequency.

| Metric | Low GSM (150–180) | Mid GSM (200–250) | High GSM (300+) |

|---|---|---|---|

| Material Cost | Low | Medium | High |

| Lifespan | Short | Medium | Long |

| Required Quantity | High | Medium | Low |

| Total Ownership Cost | High | Balanced | Low |

Summary

GSM is not just a technical spec—it’s a performance promise. When sourcing microfiber cloths for different market segments, understanding GSM empowers you to:

✅ Match the right cloth with the right use

✅ Optimize cost vs. performance ratios

✅ Differentiate SKUs under private label lines

✅ Enhance customer satisfaction and reorders

With a data-driven GSM strategy, microfiber becomes more than just a cleaning tool—it becomes a precision-engineered cleaning solution tailored for your brand.

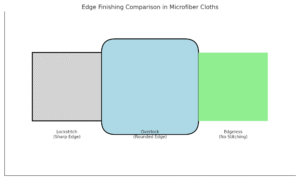

3 Why Edge Finishing Matters

When evaluating microfiber cloth quality, one of the most overlooked yet critical factors is edge finishing. It not only determines durability and aesthetics, but also affects usability, lint-free performance, and even compatibility with delicate surfaces such as glass or screens. In commercial and professional settings, a poorly finished edge can lead to faster fraying, reduced life span, and increased operational costs.

Three Main Types of Edge Finishes

To help you better understand the differences, here is a comparison of the most common edge types:

📊 Edge Finishing Comparison Chart

| Finish Type | Description | Pros | Ideal Use Cases |

|---|---|---|---|

| Lockstitch (Straight Edge) | Sewn with straight machine stitching, creating a visible seam and right-angled corners. | Durable, cost-effective | General-purpose cleaning, industrial use |

| Overlock (Rounded Edge) | Edges are rounded with serged or overlocked stitching for a more refined look. | Aesthetically pleasing, moderate durability | Household cleaning, retail sales |

| Edgeless (Laser Cut / Ultrasonic) | No visible stitching; edges are heat-sealed or laser-cut to prevent fraying. | Lint-free, ultra-soft, safe on glass | Automotive, electronics, screen cleaning |

Why Edge Choice Matters in Professional Applications

-

Durability in Frequent Use

In commercial environments (e.g., car detailing, janitorial services), cloths are washed and reused dozens, sometimes hundreds of times. Lockstitched edges may outlast overlocked options, while edgeless designs are less likely to unravel during aggressive scrubbing. -

Lint-Free Performance

When used for glass, mirrors, or electronics, overlocked or poorly sewn edges can leave fibers behind. Edgeless microfiber cloths are essential in these scenarios, offering a flawless, lint-free experience. -

Surface Protection

Sharp stitched seams may scratch high-gloss surfaces. Edgeless or rounded overlock edges reduce this risk significantly. -

Visual Appeal for Retail & Gifting

Overlocked cloths, especially in vibrant colors, are popular in B2C retail packaging because of their finished appearance. If presentation matters, this option combines form with function.

Best Practices When Choosing Edge Styles

-

For bulk-use cleaning contractors, opt for lockstitched or ultrasonic edgeless styles to reduce replacement frequency.

-

For consumer-focused brands, overlocked microfiber offers a balanced look and feel that appeals to household buyers.

-

For high-precision tasks like lens or screen cleaning, go edgeless without hesitation.

4 Choosing the Right Weave – How Texture Affects Performance

Microfiber is not just a material — it’s a structure. The way it is woven plays a huge role in how it performs during cleaning. Choosing the wrong weave can lead to underperformance, surface damage, or even wasteful overuse. Understanding how different weaves function allows businesses and distributors to match the right cloth to the right job — every time.

Common Microfiber Weave Types

Let’s explore the four most prevalent microfiber weave structures:

| Weave Type | Description | Best For |

|---|---|---|

| Warp-Knitted / Flat | Smooth surface, tightly woven pattern; thin and strong | Windows, screens, electronic devices |

| Waffle Weave | Square embossed texture; boosts water absorption | Kitchen towels, drying cloths |

| Twist Loop | Spiral loops increase surface friction and trap dirt effectively | Car detailing, heavy-duty cleaning |

| Coral Fleece | Fluffy, plush, soft pile texture with deep fibers | General-purpose wiping, dusting |

📊 Weave Type Performance Comparison Chart

👉 View chart

This chart visualizes how each weave type performs across four key attributes: absorbency, durability, softness, and general-purpose suitability.

Key Considerations by Application

🧼 Surface Sensitivity

-

Use warp-knitted or coral fleece weaves on delicate surfaces to avoid micro-scratches.

-

Avoid twist-loop on glossy or painted finishes unless explicitly required.

🚗 Heavy-Duty Cleaning

-

Twist loop excels at grime removal in automotive detailing or industrial wiping due to its friction-heavy surface.

-

Durable and machine washable, it withstands repeated rough use.

🍽 Absorbency

-

Waffle weave shines in kitchens and food service — it holds up to 8–9 times its weight in liquid.

-

The raised grid pattern improves surface contact and helps dry faster.

💎 Softness and Aesthetics

-

For consumer-facing packaging, coral fleece not only feels soft but looks lush, making it ideal for promotional bundles or gift sets.

Weave Selection Tips for B2B Buyers

-

Hospitals & Healthcare: Go with lint-free warp-knit for sanitation-sensitive zones.

-

Car Wash Chains: Use coral fleece for interiors and twist loop for exterior grime.

-

Retail Branding: Coral fleece with vibrant dyeing and overlock edging looks great on-shelf.

Choosing the right weave is not just about feel — it’s about functionality and matching the cloth’s texture to its job.

5 The Role of GSM (Weight) – Not All Microfiber Is Created Equal

When choosing microfiber cloths for industrial use, household cleaning, or private labeling, one of the most overlooked yet vital specifications is GSM — grams per square meter. This single metric influences how a cloth feels, how it performs, and what it’s best used for.

What Is GSM?

GSM stands for grams per square meter, and it refers to the density of the fabric. A higher GSM means the cloth is thicker, heavier, and often more absorbent and durable. Conversely, lower GSM cloths are lighter, faster drying, and often more economical.

Why GSM Matters in Microfiber

| GSM Range | Characteristics | Best For |

|---|---|---|

| <200 GSM | Lightweight, quick-drying, less absorbent | Disposable cleaning, promotional giveaways |

| 200–300 GSM | Balanced absorbency and cost | Everyday household cleaning, auto interiors |

| 300–400 GSM | Thicker, softer, better water retention | Car drying, hospitality use, kitchen wipes |

| 400+ GSM | Premium feel, plush, extremely absorbent and soft | High-end branding, polishing, packaging kits |

📊 GSM Performance Comparison Chart

This visual compares absorbency, durability, drying speed, and cost across standard GSM ranges. Higher GSM generally means better performance — at a higher material and manufacturing cost.

GSM & Functionality Correlation

-

Lower GSM (180–220): Great for high-turnover tasks like industrial janitorial usage. Lower material cost means they can be disposed of after short-term use.

-

Mid-Range GSM (250–320): The sweet spot for most cleaning scenarios. Absorbent yet not too bulky. Common in B2B automotive and home cleaning bundles.

-

High GSM (350–500): These cloths perform best in tasks requiring both absorbency and visual quality — think spa towels, premium car detailing, or branded microfiber kits.

Tip: GSM is also a deciding factor in shipping costs — higher GSM = heavier weight per unit = higher freight. When quoting, always align GSM with end-use expectations and logistical realities.

Meet Clean Recommendation

At Meet Clean, we offer full customization from 180 GSM to 450+ GSM. We advise distributors and retailers to tailor GSM by channel:

-

Wholesale bulk B2B: 200–280 GSM

-

Retail packaging / promotional use: 280–350 GSM

-

Premium brand collections: 350–450 GSM

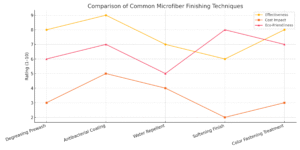

6 Finishing Techniques & Coatings – Enhancing Microfiber Performance

While GSM and weaving define a microfiber cloth’s structure, the finishing treatments determine its surface behavior, safety, and long-term functionality. The right coatings or washes can dramatically affect cleaning efficiency, durability, and even branding.

Common Finishing Processes for Microfiber

-

Degreasing Prewash

-

Purpose: Removes manufacturing oils and impurities from fibers.

-

Benefit: Boosts absorbency by up to 30% and ensures streak-free performance.

-

Application: Especially important for car care and glass-cleaning cloths.

-

-

Antibacterial Coating

-

Purpose: Prevents bacterial growth and mildew.

-

Benefit: Ideal for kitchen, bathroom, and pet-use cloths; supports longer shelf life in humid climates.

-

Certification: Can be enhanced with OEKO-TEX® and BPR-compliant silver ion solutions.

-

-

Water Repellent Treatment

-

Purpose: Creates a hydrophobic layer to resist liquid penetration.

-

Trade-Off: Reduces absorbency but adds durability for industrial wiping.

-

Usage: Great for machinery, oil residue, and heavy-duty factory surfaces.

-

-

Softening Finish

-

Purpose: Adds plushness without changing GSM.

-

Benefit: Increases tactile appeal, especially for boxed or gift-packed items.

-

Note: Common in retail-ready towel or facecloth packaging.

-

-

Color Fastening Treatment

-

Purpose: Ensures long-lasting, fade-resistant color retention.

-

Relevance: Crucial for dark tones or multicolor patterns that undergo repeated washing.

-

Added Value: Enhances perceived quality in hospitality or high-use environments.

-

📊 Finishing Comparison Chart

The chart compares Effectiveness, Cost Impact, and Eco-Friendliness across these finishing options. While antibacterial coatings offer strong performance, degreasing remains the most universally applicable and cost-effective treatment.

Eco Considerations in Finishing

-

Avoid solvent-based coatings unless required for industrial use.

-

Meet Clean offers water-based antimicrobial finishes with EU and Japan safety compliance.

-

Recyclability is best preserved with single-layer finishes over laminates.

Tip: The finish must align with your final market. For instance, antibacterial cloths do well in Japan and Singapore, where hygiene demand is high, while soft-touch finishes work better in European premium retail channels.7 Custom Printing, Labeling & Branding – Building Identity Through Microfiber

Microfiber isn’t just a cleaning tool — it’s a branding medium. In today’s competitive retail and B2B environments, packaging alone is no longer enough. Your product needs to carry your brand — quite literally — and microfiber’s soft surface is ideal for doing just that.

1. Heat Transfer Printing

Ideal For: Brands that prioritize visual impact, such as cosmetics, events, or premium homeware kits.

2. Embroidery or Woven Label

Tip: Place embroidery in the corner or on a label tag for visual branding without impairing functionality.

3. Laser Engraving & Embossing

Technology: Especially effective on suede or leather-like microfiber.

Aesthetic: Minimalist, elegant, no color — ideal for luxury gifting or modern packaging.

Considerations:

Not suitable for all fabric types

Requires precision alignment and low-GSM loss

4. Hang Tags & Custom Packaging Elements

Combine packaging with story-driven branding:

“Eco message” hang tags

QR code for usage instructions or product series

Product benefit icons (e.g., odor-resistant, machine washable)

Adds retail shelf appeal without altering the cloth itself

Easy to adapt for promotions or region-specific campaigns

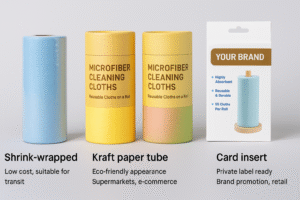

📌 Packaging Types That Work Well with Branding:

Packaging Type Best Branding Method Kraft Tube Laser logo, printed sleeve Shrink Wrap External label or hang tag Paper Card Backing Full-color card branding Box Draw Packaging In-box leaflet, printed box

5. Private Label Strategies for OEM Clients

At Meet Clean, over 70% of export orders involve private labeling. Here’s how to streamline the process:

MOQ Flexibility: Start with 1,000–3,000 pcs for printed logos or 5,000+ for woven tags.

Production Timeline: 10–15 days added for logo integration or embroidery.

File Requirements: Vector logos (AI or PDF), Pantone codes for color match.

🧩 Want to Stand Out?

Introduce seasonal colorways with matching packaging.

Offer reusable pouches with brand design for retail kits.

Combine QR + branding: Track usage, engage buyers, and reinforce brand recall.

📈 Results from Private Label Programs

Home cleaning brand in the US saw a 22% reorder uplift after shifting from plain cloths to branded tags.

Japanese auto care chain improved in-store sell-through by 30% with embroidered logo sets in kraft tube packaging.

EU-based beauty brand bundled heat-transferred logo towels with skincare products and doubled AOV in Q3.

8 Packaging & Presentation – Aligning Form with Function & Market

In the world of microfiber OEM and wholesale, packaging does far more than protect the product — it’s a strategic tool. Whether you’re selling to industrial suppliers, retail chains, or e-commerce customers, packaging defines first impressions, shipping efficiency, and brand value.

Let’s explore how packaging choices impact perception, costs, and use-case alignment.

1. Key Packaging Formats & Their Applications

Packaging Format Advantages Best For Shrink Wrap Economical, compact, tamper-proof Industrial supply, factory use Kraft Paper Tube Premium look, recyclable, stackable Retail, Amazon, gift kits Paper Card Pack Customizable, cost-efficient, low MOQ Supermarket, resellers Box Draw Packaging Clean layout, high-end retail impression Personal care, home improvement Plastic Bag (50 pcs) Budget bulk format, stackable in cartons B2B bulk buyers, car washes 📦 Visual Comparison Coming Up…

📊 [Image Generated]

A visual side-by-side comparison of 5 packaging styles showing their look, volume efficiency, and target channel.✅ Click to view the 4:3 infographic packaging layout here (already generated)

2. Cost & Value Considerations

Packaging Type Cost (Est.) Perceived Value Labor Intensity Shrink Wrap Low Low Low Kraft Tube Medium-High High Medium Paper Card + Hang Tag Medium Medium-High Medium Box Packaging High Very High High 💡 Tip: For online retail, high-value packaging = stronger unboxing experience = lower return rate.

3. Align Packaging with Sales Channel

Retail Shelves → Needs strong visuals & storytelling: full-color cards, hang tags, transparent window boxes

Amazon / E-commerce → Focus on stackability, unboxing experience, recyclable elements

Wholesale / Industrial → Prioritize volume, packing efficiency, carton handling

4. Sustainable Packaging Options

Meet Clean offers:

FSC®-certified paper tubes

Soy-based inks for printed cards

Biodegradable shrink film (on request)

QR codes for paperless manuals

🌱 Packaging isn’t just aesthetic — it’s also a compliance matter in EU, Canada, and parts of the US (e.g., California SB 343).

5. Case Study: Packaging Influence on Buyer Behavior

A Singapore reseller rebranded their microfiber kitchen roll into kraft tubes with recipe-themed card wraps — and saw a 70% revenue lift in Q1.

A French cleaning supplies distributor cut 25% shipping cost by moving from box packaging to compressed shrink-wrap packs for wholesale clients.

📦 In short, choose your packaging not only based on budget — but based on:

Who will receive it

Where it will be seen

How it will be used

9 MOQ, Lead Times & Supply Chain Optimization

In OEM microfiber production, operational agility often trumps price. Clients demand reliability, speed, and predictability — all of which hinge on how well supply chains are configured.

This chapter addresses minimum order quantities (MOQ), production cycles, lead times, and how to work with manufacturers (like Meet Clean) for optimal outcomes.

1. MOQ Explained

Standard MOQ for microfiber cloths: 3,000–5,000 pcs per color/style

Printed or embroidered logo MOQ: 1,000–3,000 pcs (based on method)

Custom packaging MOQ: 2,000 pcs for branded kraft tubes; 5,000 pcs for full-color box printing

📌 Why MOQs Matter:

Lower MOQs = less cost-efficient production due to dyeing, setup, and packaging line preparation

But flexible MOQs help smaller brands or new product lines enter market faster

2. Production & Lead Times

Stage Typical Time (Working Days) Fabric weaving & dyeing 7–10 days Cutting & sewing 3–5 days Logo printing or embroidery 5–7 days Packaging & QC 2–3 days Total lead time 15–20 working days 📦 For repeat orders with same color/style: 10–12 working days

⏱ Express Service: Meet Clean offers 7-day rush production for stocked colors/materials.

3. Shipping & Logistics

FOB Qingdao / Shanghai is most common for bulk clients

For US/Canada: 12–20 days via sea, 5–8 days via air

For Europe: 28–35 days by sea, 6–9 days by air

Courier samples via DHL/UPS/FedEx: 3–5 days globally

🔍 Tip: We recommend consolidating packaging and outer carton specs early to avoid rework delays.

4. Supply Chain Resilience Tactics

Dual Sourcing Materials: Meet Clean maintains 2–3 fabric suppliers per style

Seasonal Planning: Encourage clients to forecast Q3 orders by May for uninterrupted fulfillment

Warehouse Stocking: 10% overproduction buffer can be held locally for recurring buyers

5. Common Supply Chain Challenges

Issue Solution by Meet Clean Port congestion Alternate ports & priority lanes Material shortage (e.g., dyes) Prebooking + supplier tier system Sudden volume spike Modular production scheduling Communication gaps Dedicated bilingual account manager

6. OEM Support for B2B Clients

At Meet Clean, we provide:

Real-time production updates

Photo QC reports at each milestone

Flexible documentation: Commercial invoice, packing list, MSDS if needed

Multichannel logistics coordination: sea, air, courier, local agent

📦 Result: 95.3% on-time delivery in 2024

10 Summary – Key Takeaways for Sourcing Smarter

Microfiber cloths are deceptively simple products — but optimizing their manufacturing, branding, and supply chain takes multi-dimensional thinking.

🧠 What You Should Remember:

Fabric counts: Understand GSM, yarn split, and weave type

Finish matters: Different coatings and edge stitching alter performance

Packaging is perception: Match your channels with visual + functional packaging

Lead time ≠ speed: Smart planning saves both time and cost

Brand it right: A logo can turn a cloth into a brand ambassador

✅ Want to go from basic microfiber to professional-grade B2B product lines?

📞 Contact Meet Clean for:

Samples with your logo

Custom packaging designs

Tiered pricing for bulk MOQ

🌐 Visit our OEM page or message our team directly to schedule your 1-on-1 sourcing consultation.

Appendix: Visual Aids & Strategic Charts

To better support decision-making and visualize key insights, here are recommended infographic/chart sections you can use in your post or sales materials.

A. Fabric GSM vs. Application Chart

Purpose: Help B2B buyers select fabric weights based on cleaning scenarios.

| GSM Range | Application Scenario | Notes |

|---|---|---|

| 180–220 | General-purpose wiping (kitchen, bathroom) | Fast-drying, light & foldable |

| 220–280 | Car care, household glass | Better water absorption, softer touch |

| 300–360 | Industrial degreasing, oil-heavy tasks | Higher durability & reusability |

B. Microfiber Edge Stitching Comparison

Purpose: Educate buyers on edge finish options and benefits.

| Stitching Type | Durability | Appearance | Common Use |

|---|---|---|---|

| Lockstitch (直角锁边) | ★★★★☆ | Precise lines | Car care, mirror polishing |

| Overlock (包缝) | ★★★☆☆ | Smooth corners | Household use, minimal fray |

| Ultrasonic/No Stitch | ★★☆☆☆ | Sleek, clean | Disposable rolls, budget kits |

C. OEM Process Flowchart

Purpose: Guide importers or wholesalers through the custom production journey.

Steps:

-

Inquiry → 2. Quotation → 3. Sample Approval → 4. PO →

-

Mass Production → 6. QC → 7. Packaging → 8. Shipping → 9. Feedback & Repeat Order

D. Cost Breakdown Chart

Purpose: Clarify unit price build-up to emphasize value over price.

| Component | Approx. Share (%) |

|---|---|

| Raw Material (Fabric) | 35–45% |

| Cutting & Sewing | 10–15% |

| Printing / Logo | 8–12% |

| Packaging | 8–20% |

| Overhead & QC | 10–12% |

| Margin (before shipping) | 10–15% |

11 FAQs – Microfiber OEM Insights

Q1: What’s the minimum viable quantity for starting a private label microfiber line?

A: As low as 3,000 pcs/style is possible with standard colors. For custom PMS colors or multi-pack SKUs, expect 5,000 pcs+.

Q2: Can I mix SKUs or colors in one container to reduce costs?

A: Yes. Consolidation is supported. You can mix up to 4–5 SKUs per shipment without extra cost if packaging is unified.

Q3: What certifications can you provide?

A: We offer OEKO-TEX®, ISO9001, REACH, and customized MSDS reports for specific chemicals used in coating or colorfastness.

Q4: How does microfiber compare to bamboo or cotton cloths in lifecycle cost?

A: Microfiber outlasts cotton by 5x and bamboo by 2–3x in washing cycles. It also requires less detergent and water per use.

Q5: Are you able to support third-party fulfillment or dropshipping?

A: While our focus is OEM/B2B, we can prep barcodes, retail packaging, and deliver to 3PL warehouses like Amazon FBA.